Art & Design in Motion

ARESE RH95 is a 2 seater rear central engine,

essence of the italian sports car.

By and for True Enthusiastes

ARESE RH95, a name reflecting 95 years of Touring Superleggera heritage, our commitment to the future at our home on Via per Arese, an area long known as the standard-bearer for outstanding Italian design, as well as the initials of the ARESE project’s founding patron. ARESE RH95 was born to share our passion for traditional custom coachbuilding.

Bright and Theatrical

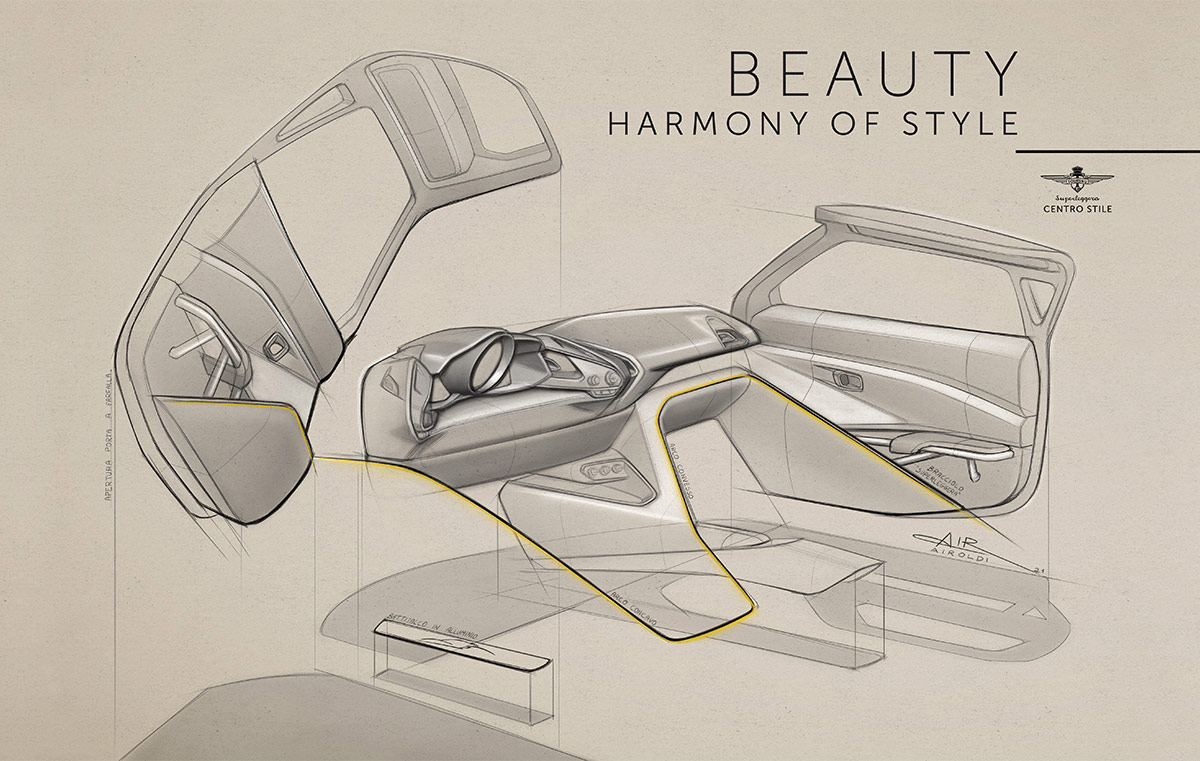

ARESE RH95 expresses a touch of drama in all its features, and if the novel scissor doors are its most striking expression, every detail is fascinating but subtle. From the bright aluminium side-slash briskly interrupted by the front wheel arch, then continued elegantly along the waistline, inspired by the Disco, to the grille and front air nostril treatment derived from AERO 3, every flank and panel offers a visual delicacy.

Aero Identity

Touring’s new ARESE RH95 represents the cornerstone of the Aero range, perfect synthesis between the sinuous volumes and ideal proportions of the Disco Volante, and the aggressive and powerful form of the AERO 3.

ARESE RH95 reflects the stylistic features of the entire AERO line in its many distinctive elements, and the cinematic openings.

Dorsal Scoop

The dorsal scoop is the car’s emblematic feature, simultaneously bold and functional, optimizing forced air circulation in the engine compartment.

Aside from this dorsal, the shoulder air inlets and a corresponding rear outlet, the sleek rear body contours are otherwise simple and quite voluptuous, with not even a trunk opening to mar the fluid shape of the rear aspect.

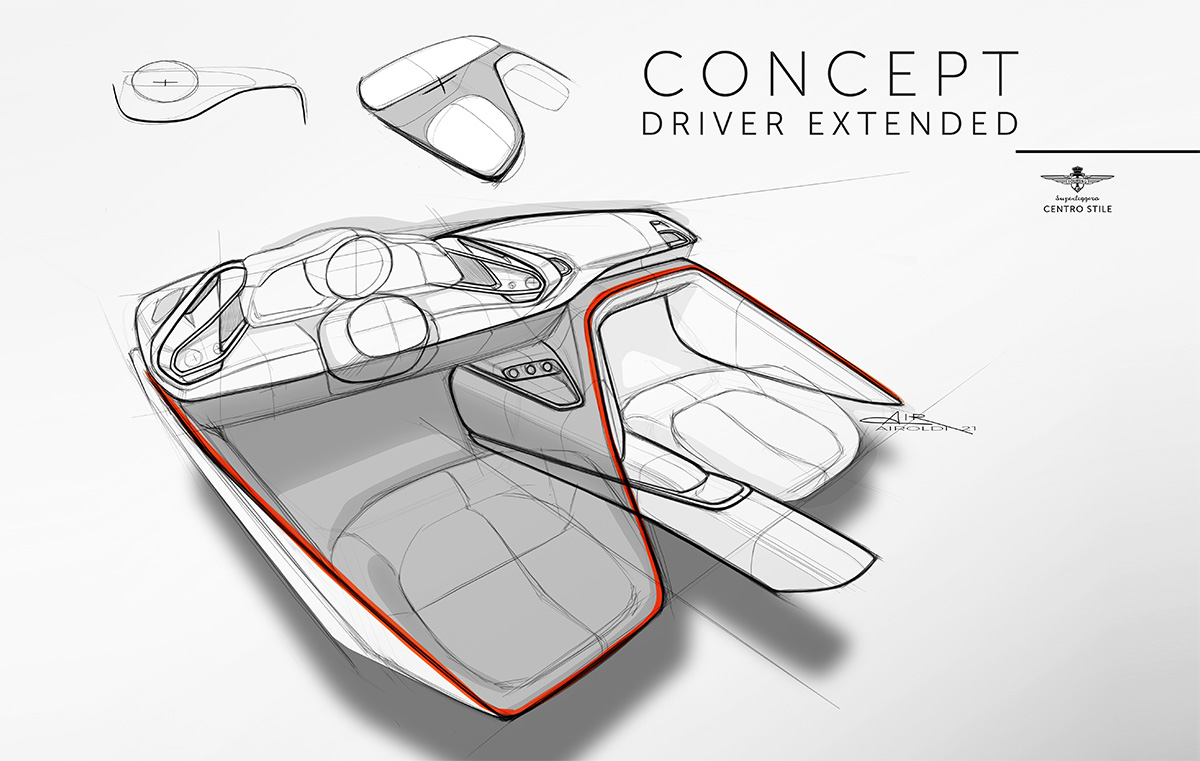

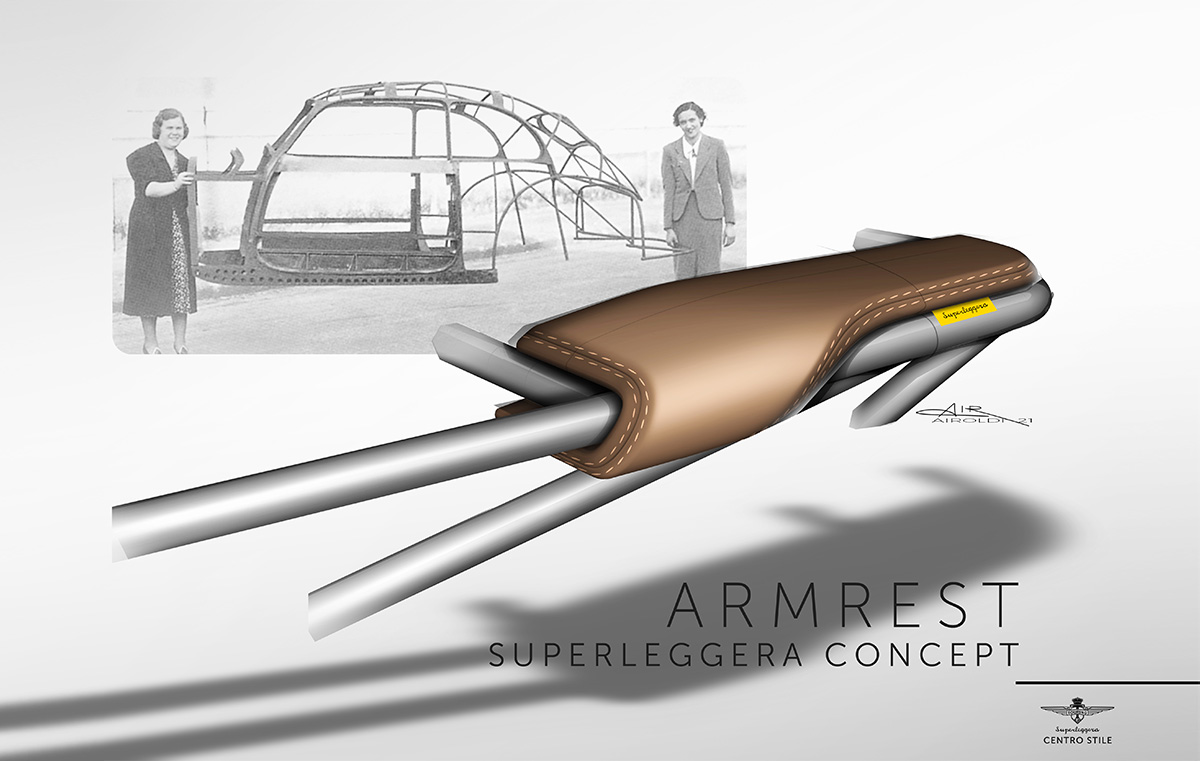

ARESE RH95’s interior is designed around the Aero “Cocoon” concept: individualized cockpits for driver and passenger, providing each with the most pleasurable experience possible.

Further enhancing this individualization, a new bespoke Touring Pattern seat facing will be monogrammed, like the finest tailored shirts, with the hand-stitched, small and discreet, initial “T”.

Technical Specifications

Dimensions

Length:4782 mm

Width:1982 mm

Height:1259 mm

Wheelbase:2650 mm

Fuel tank capacity:78 litres

Engine

Cylinders / Type:V8, 90°

Nominal output:670 hp @ 8000 rpm

Maximum torque:760 Nm

Emission level:Euro 6

Fuel consumption, EU drive cycle

Combined:11,4 l/100 km

CO2 emissions (combined):260 g/km

Driveline

Rear wheel drive - 7 F1 DCT automatic gear transmission

Wheels

Front tyres:245/35R20

Rear tyres:305/30R20

Wheel type:Touring Superleggera

Performance

Top speed (est.):330 km/h

Acceleration (est.) 0-100km/h:3,0 sec

As unique as you are

Specially constructed according to the customer’s instructions, so ensuring a high degree of personalisation, each Touring ARESE RH96 will be a unique example of the fuoriserie art.

This is a car with a strong character, with highly distinctive features, so it is entirely appropriate that the owner’s own personality is stamped on it from the beginning. Exotic materials and unusual colours produce a finished product with its own distinct style.

The customer is encouraged to be as imaginative as they like to create their own masterpiece, always with the expert guidance of Touring’s stylists to provide ideas.

A journey to creation

Touring Superleggera Design Team will guide you into the journey of Touring ARESE RH95 creation: from moodboards to panel of materials, together with you, the Design Team will create a very unique personality to your ARESE RH95.

ARESE RH95 is more than a name, it is a Club of 18 bespoke masterpieces

Hi-Tech Materials and Skilled Craftsmanship

Breaking with tradition, the entire body is made from carbon fibre.

This advanced material provides benefits in terms of weight and strength, and to ensure a flawless finish components are scanned and logged to confirm millimetre accuracy with the design parameters.

Cognisant from the earliest days of the industry that weight is the enemy, Touring Superleggera has returned once again to carbon fibre for the ARESE RH95 coachwork. The thicknesses and orientation of the strands are selected for the best weight/stiffness ratio, and in the preparatory phase, the optimal use of materials was analyzed in terms of overall weight, strength, surface appearance and durability.

All components are CAD-designed and computer verified.

Quality is our Goal

Quality control is paramount, with extreme attention paid to ensure the end product is perfect.

Checks are made at all stages of production: body in white, after painting, assembly and road testing.

Only by hand-building the car can we achieve the level of perfection for which we aim, and to this end our craftsmen spend 5,000 hours on each car.

The story behind the legend